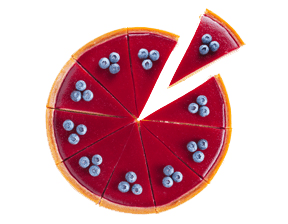

Ultrasonic cutting for a remarkable presentation of your products

If you have problems with your conventional cutting technique, such as food constantly sticking to the blade, low cutting speed, and a cut that is not as clean as you desired, you will definitely find a solution from the Matissonic product line. Whether it is for your pastries, granola bars, cheeses, deli meats, or prepared meals, your cut and size quality will be upgraded.

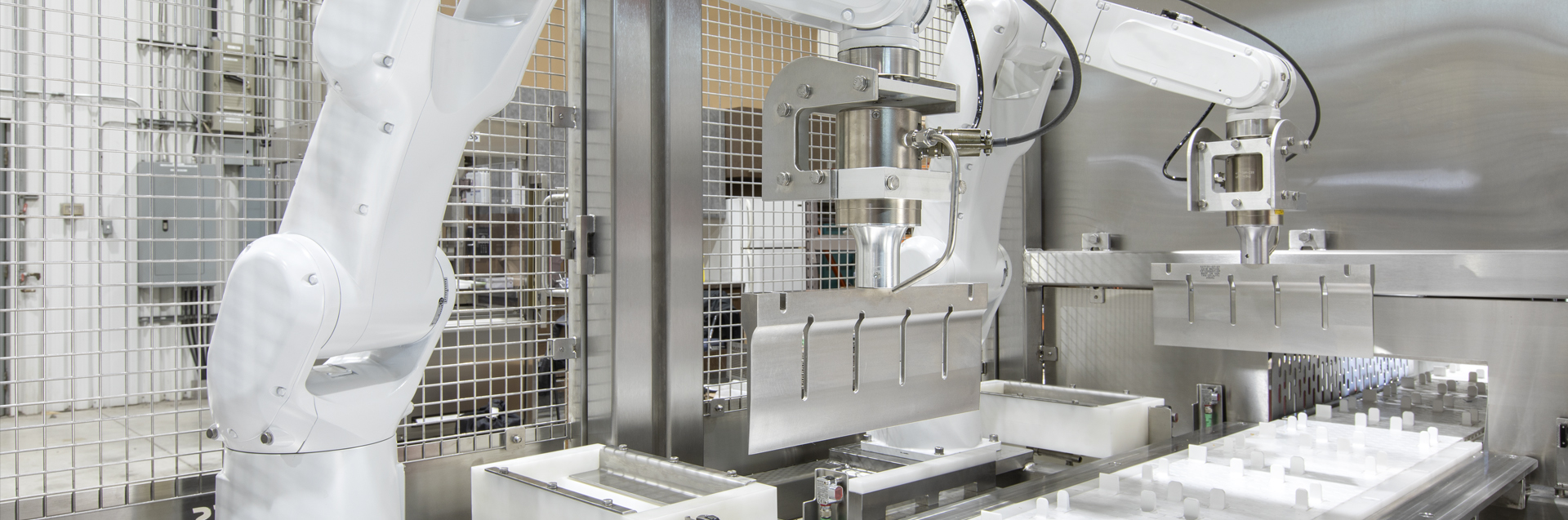

Matissonic BUILDS UNIQUE PIECES OF EQUIPMENT YOU WON’T FIND ANYWHERE ELSE

All our customers’ products are first evaluated to assess their level of compatibility with ultrasonic technology. Our experts will analyze your product with this technology to optimize your production: speed, cutting quality, precision, etc. In addition, our designs and products can be adapted to your existing and future production lines through the development of customized layout plans. To ensure the safety of your operators, all our pieces of equipment comply with strict security standards. They are also designed to facilitate your cleaning operations. Providing sturdy and durable equipment is one of our main priorities; therefore, we select industrial-grade components from our world-renowned suppliers. Finally, our pre-programmed operator interfaces are user-friendly and allow for uninterrupted communication between you and your equipment.

DISCOVER WHICH OF OUR SPECIALIZED EQUIPMENT

YOU NEED TO CUT YOUR PRODUCTS!

Click the image corresponding to your desired product to see all pieces of equipment compatible with the type of cut you need.

BENEFITS OF CHOOSING Matissonic?

POWER, SPEED, RELIABILITY, AND PRECISION

These words echo through your head, but how do we actually apply them? First, we analyze your production process to find a way to automate it. Second, we integrate compatible systems and components to maximize power and production speed. That’s how we reach peak performance.

HIGH-PERFORMANCE ULTRASOUNDS

To validate that ultrasonic cutting is the right technology for your application, we test the cuts on your products prior to the sale of any equipment. Thus, you can already assess the quality of the cut and get confirmation that the targeted performance in operation will be reached.

SUPPORT

We will perform Factory Acceptance Testing (FAT) before delivery and after installation at your plant (SAT). Not only will we test the quality of the equipment, but also, we will teach you everything you need to know about its use down to the last detail. In the end, all you will have to do is contact our customer service department if you need further assistance.

EASY CLEANING

You will get stainless steel machines designed and built according to the highest sanitary standards for the food industry. Additionally, we will train your cleaning staff who will routinely maintain the equipment for maximum longevity.

SAFE ACCESS TO MACHINES

Whether it is for risk analysis, redundancy of security systems, lockout methods, or security guards, our design and manufacturing engineering team designs systems that meet the security standards required for your operations.

EASY MAINTENANCE

It is worth mentioning that we pre-select low-maintenance industrial components and that our designs provide the maintenance staff with easy access to perform their job. We also provide a maintenance schedule, with the operation and maintenance guide included with each Matissonic piece of equipment.