In the cutting of food products using ultrasonic cutting, particularly in industrial environments, the ultrasonic blade technology offers advantages that optimize the efficiency and quality of agrofood production.

Thanks to ultrasonic blades vibrating at a high frequency, the quality and compliance of the cut is ensured, even with products that are considered more complex to cut. We have ranked the main reasons to use ultrasonic cutting in your food production.

ADVANTAGES THAT MAKE THE CUT!

• No pressure, no crushing

• Self-cleaning effect

• Better added value of product

• Easier cleaning

• Adapted to automation

• Guaranteed versatility

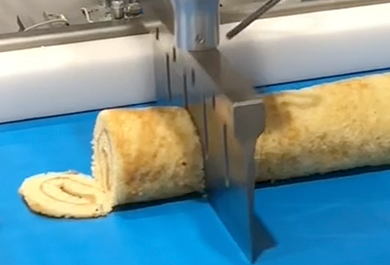

The ultrasonic blades vibrate at a very high frequency (~20 kHz), thus reducing friction during the cutting process, for a neat and precise cut. These precision cuts can be performed on even soft, sticky, or mixed texture products such as cakes, cheeses, sandwiches, bars, and raw dough; while reducing loss of products that are non-compliant with your quality standards.

The vibration of the ultrasonic blades allows for cutting without pressure exerted on the food, for less products that are crushed or deformed by the cutting process. This technology is ideal for fragile or delicate products (rolls, pastries, multilayer products).

The ultrasonic blade technology creates a self-cleaning effect limiting the adhesion of the product on the blade. The reduction of products sticking onto the blade is a key advantage in food cutting production. Less adhesion translates to a significant reduction of machine downtime for cleaning, thus leading to enhanced production rates.

Cleaner cuts also translate to a reduction of sticky or deformed residues, which means there is less production waste and less losses. The better added value of the product increases your production rates while also optimizing presentation for the consumer.

As there is less contact with the product, cleaning is easier (a self-cleaning system in water is possible). In addition to this decrease in cleaning time, industry hygiene standards compliance is made simpler and ensured by optimized hygiene.

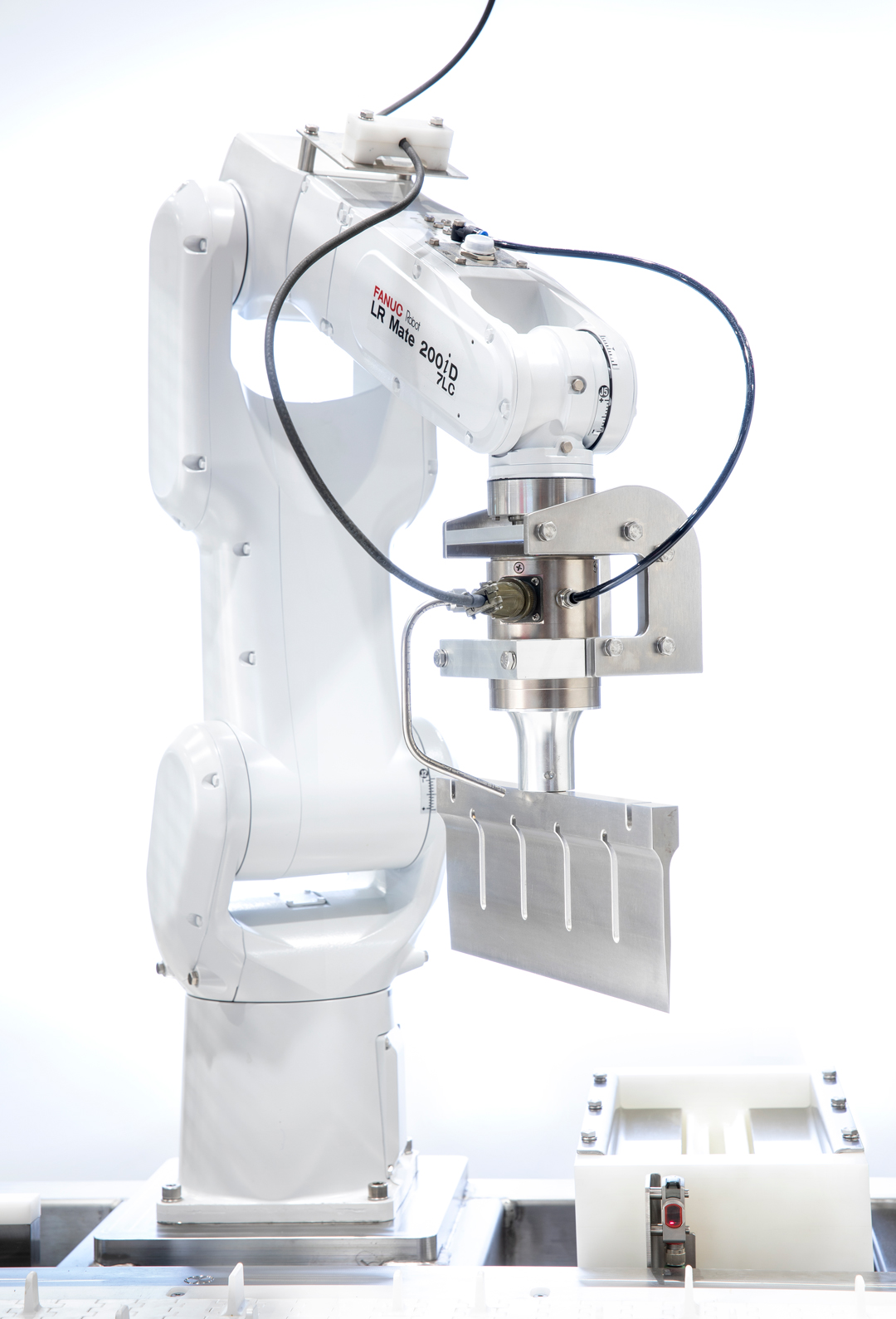

This technology that is adapted to automation is easily integrated to automated production lines with robots. Furthermore, it is also compatible and operable with inline or continuous production, and with or without a vision system.

This extensively versatile technology adapts to and is suited for room temperature, frozen, soft food products, and even very sticky ones. Ultrasonic cutting can apply to a wide variety of products, whether its bars or other foods, or if the product is round, square, individual, etc.

In conclusion, ultrasonic cutting can be the perfect solution for an extensive list of food products. Be it cakes, pastries, protein bars, cheeses, sandwiches, pasta, fruit-based products, blocks of raw dough, etc.; enhanced performance and presentation are ensured by this cutting-edge technology.

To learn more about optimizing your production, contact us now!