OUR EXPERTISE

MatissEquipment offers innovative and customized solutions that will meet your needs. Discover how our expertise, combined to yours, can speed up your production.

DISCOVER OUR SOLUTIONS

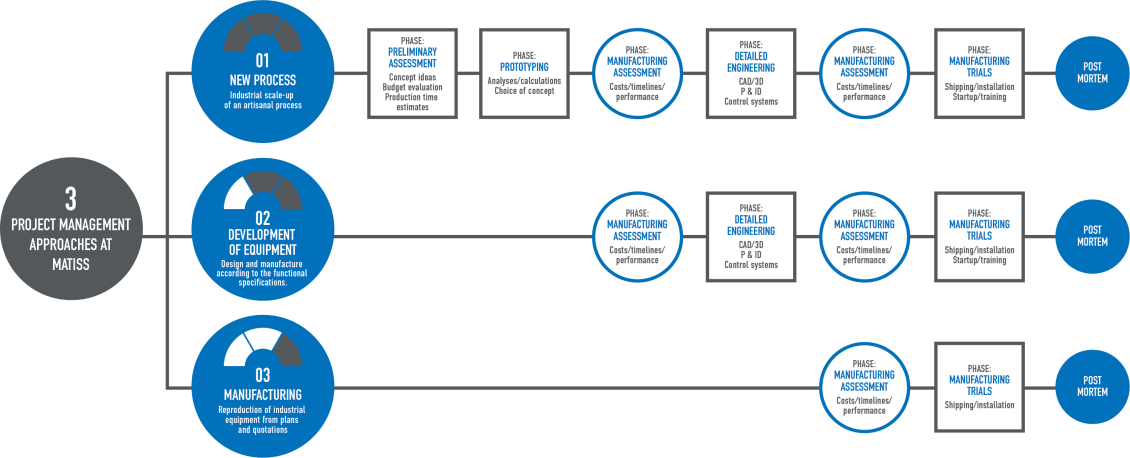

Project management

MatissEquipment proposes three management solutions, supervised with a customized project management :

Here is a personalized project approach designed for you

Whether it’s for a brand-new manufacturing process, the development of new equipment to integrate into your operations or to manufacture according to your plans and quotations, we have the resources to carry out your project. Our teams actively participate in the structure and development of your automation projects to maximize your performance.

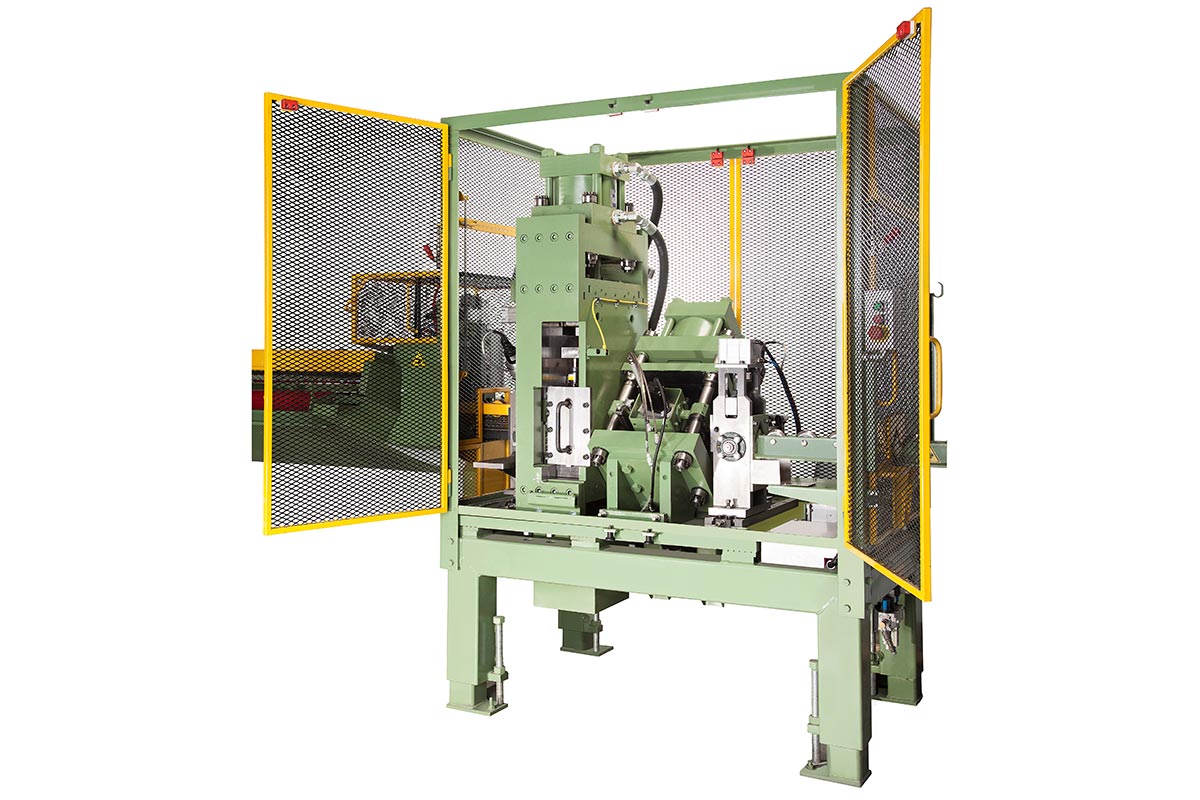

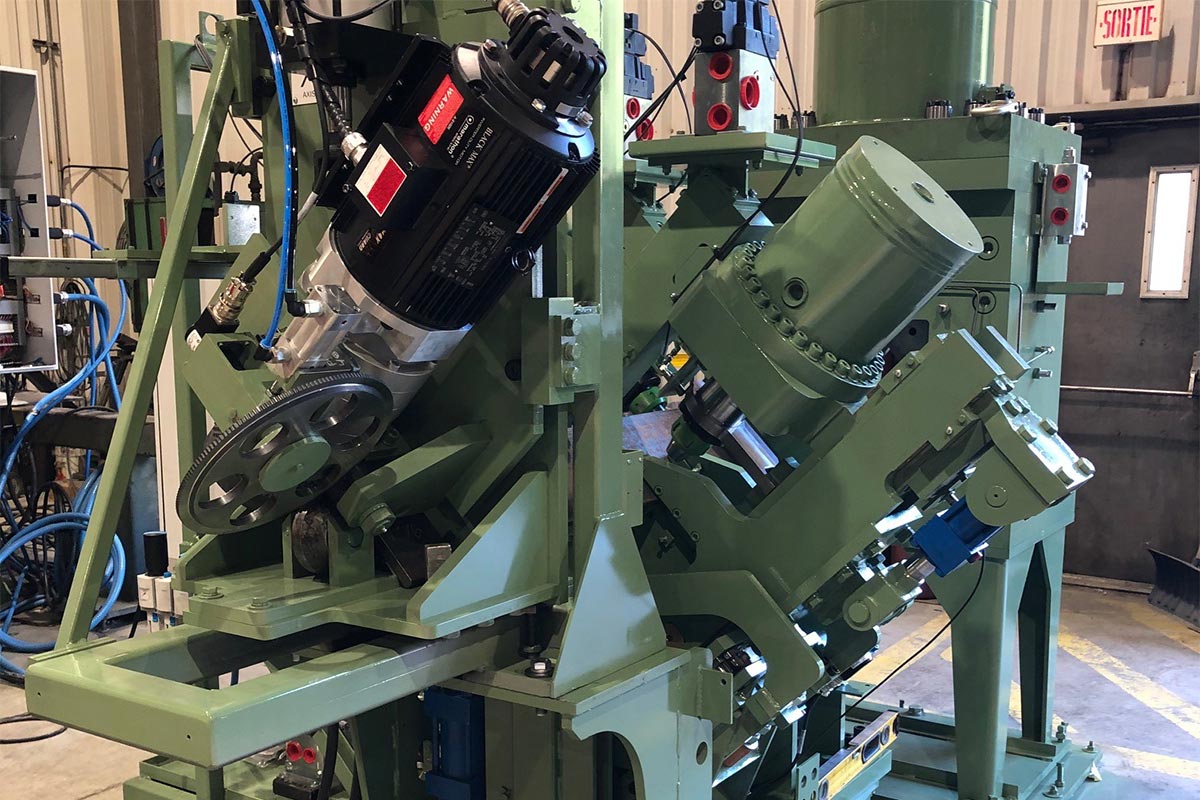

Custom manufacturing

MatissEquipment offers an experienced team to design and build equipment that serve a specific purpose.

Find a manufacturing plant for your equipment

How long have you been looking for a company to manufacture your equipment? Discover an organization that offers all the services needed to engineer and manufacture automated machinery under one roof! The MatissEquipment division manufactures its own equipment and yours inside its 35,000-square-foot plant, which includes all the facilities and services one can need:

- CNC and conventional machining

- Welding: steel, stainless steel, and aluminum

- Mechanical, electric, pneumatic, and hydraulic assembly

- Trials, prototyping, and industrial scale-up

- Equipment refurbishing (mechanical, electrical, and pneumatic control systems)

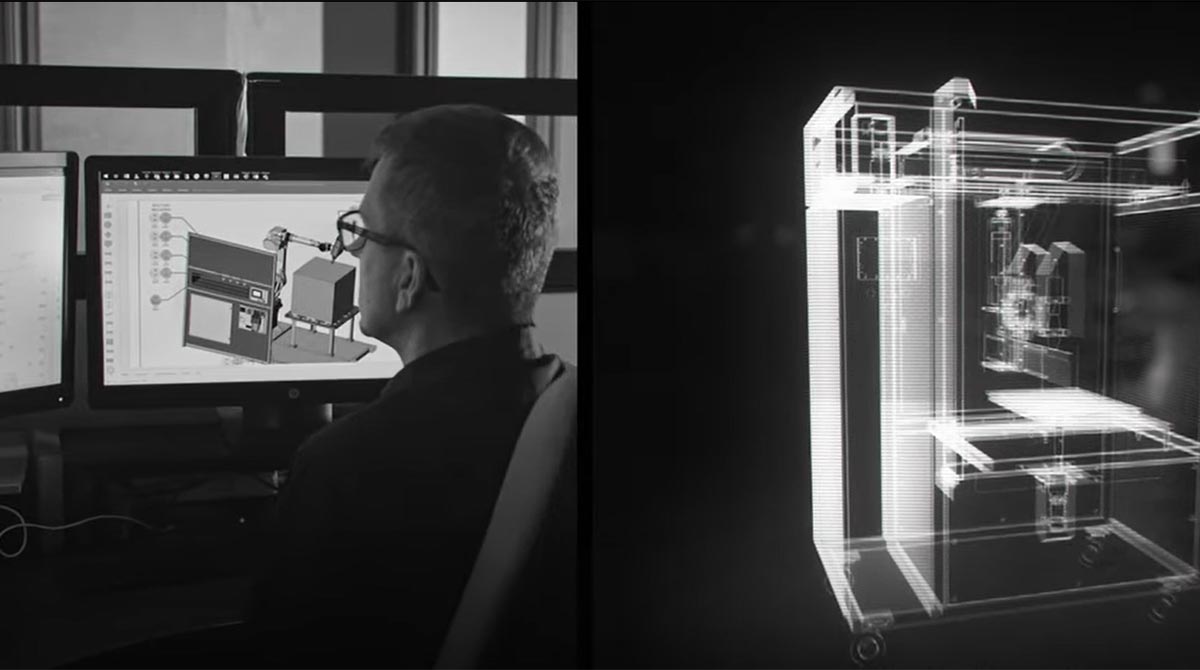

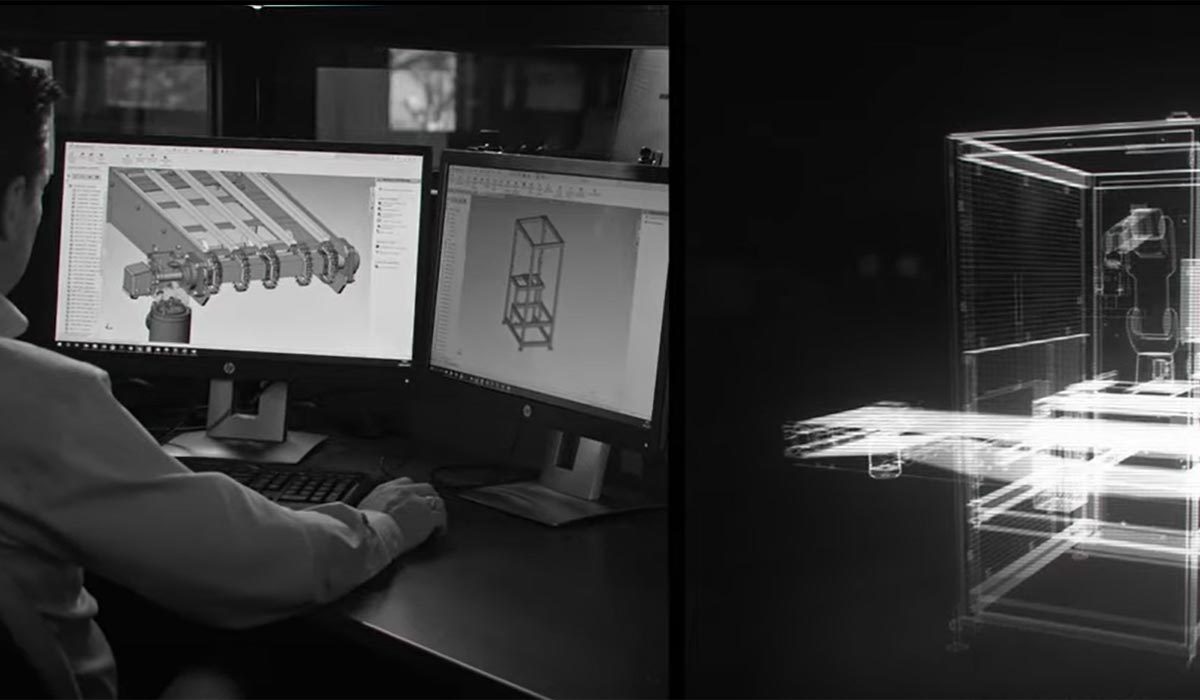

MECHANICAL ENGINEERING

MatissEquipment offers support with a mechanical engineering team focused on innovation and performance for your equipment and processes.

How to optimize your production line?

At MatissEquipment, we never lack inspiration when it comes to mechanical engineering. Imagine a whole team of designers working to create the equipment of your dreams. We study each step of your transformation process and then use 3D simulations to transform your equipment until we reach the final product. Check out our range of mechanical engineering services:

Design engineering

- Elaboration of functional specifications

- Mechanical design

- Calculations

- Finite element analysis

- Component selection

- Integration of electrical engineering and automation components

- Secure access to machines (certified CSA/OSHA)

Manufacturing engineering

- Drafting

- List of materials

- Estimates

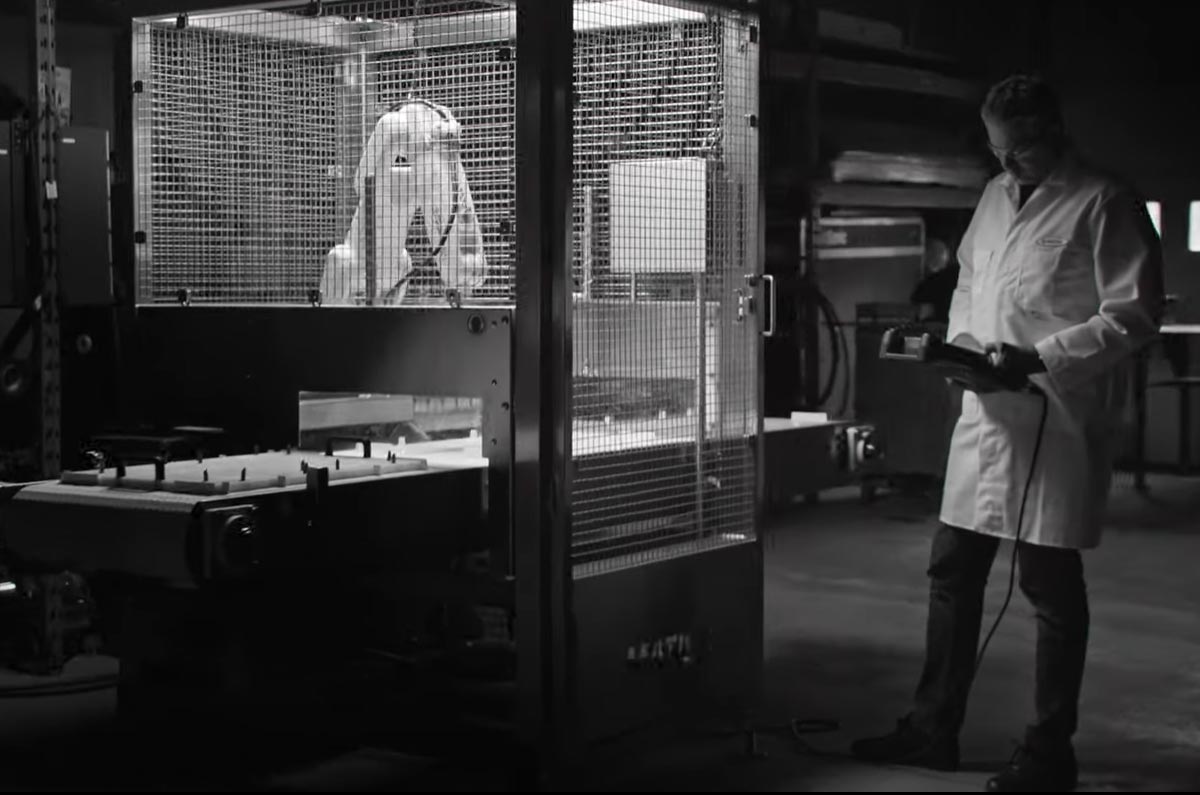

ELECTRICAL ENGINEERING

MatissEquipment offers a team at the cutting edge of technology.

Electrical engineering applied to automation

Electrical engineering is the doorway to automation! It is the central nervous system of the entire production line. Thus, you need experts who understand all its complexity and who will select the best methods and components to provide your manufacturing process with: power calculation, positioning and detection of products, control system, user-friendly operator interface, programmable logic controller, communication link with the computer network, etc. Discover the extensive range of knowledge within our electrical engineering team.

Control and instrumentation

- Process and instrumentation diagram

- Instrumentation selection and supply

- PLC control system engineering

- PLC selection and supply

- PLC programming and integration

- Secure access to machines (certified CSA/OSHA)

Power and control panel

- Control panel selection

- PLC panels

- Motor control centers

- VFD, soft start, and starter panels

- CSA, UL, and CE certifications

Electrical power design

- Electrical entry

- Power distribution

- Power factor control

- Electrical installation