ROBOTIC SOLUTIONS

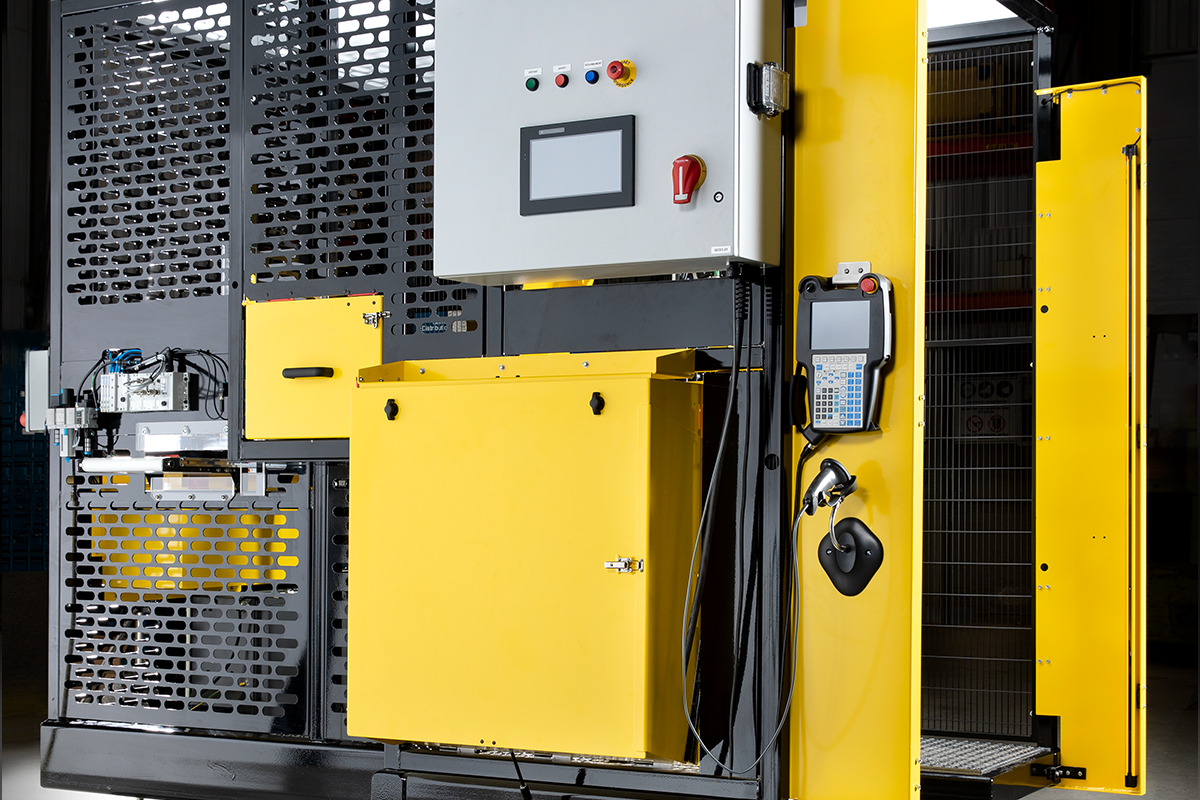

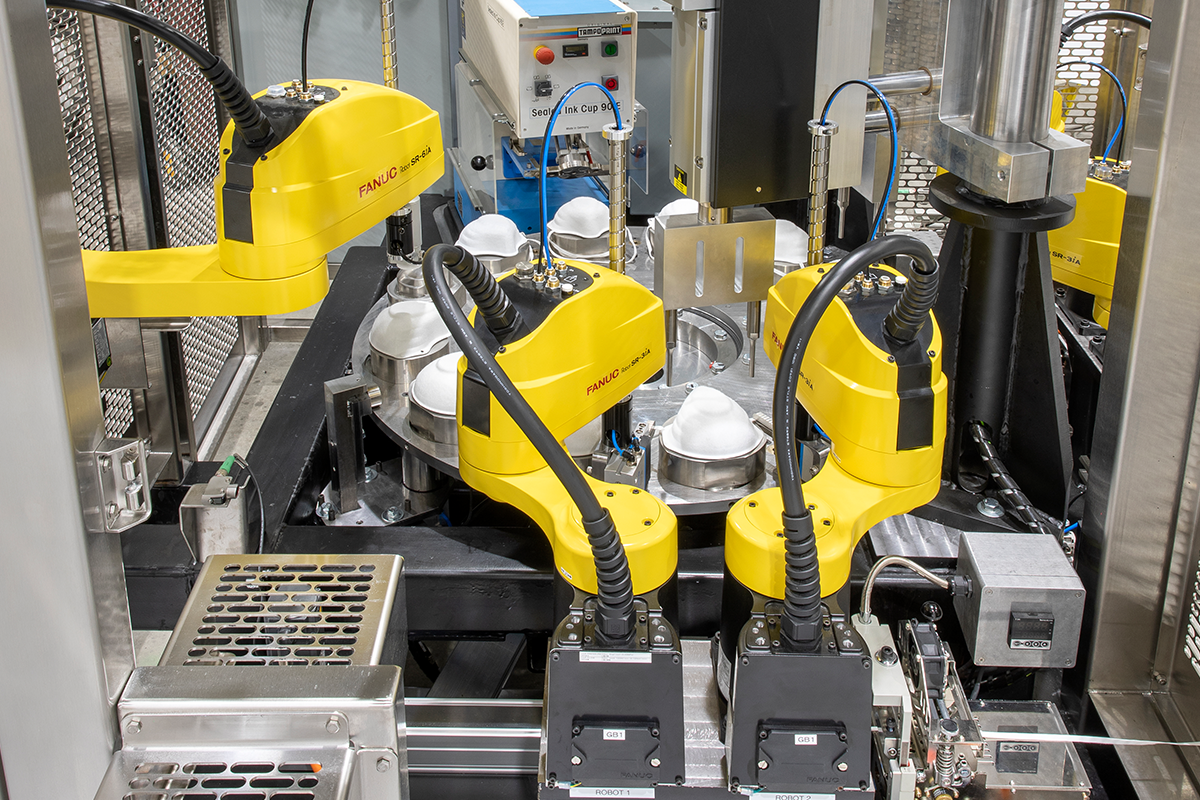

MatissEquipment designs robotic solutions for companies seeking to improve the automation of their transformation process.

How can a robot contribute to the success of your business?

A manufacturing process is a sequence of tedious tasks and configuration changes that allow you to produce a complete range of different products. Imagine the versatility you could have if a tool were to adapt to these numerous changes—that’s the power of our robotic solutions. It is now possible to adapt the functionality of a robot to the specificities of your production facilities. Here is a list of general features applicable to all sectors:

- Artificial vision

- Robot tools

- Synchronization with electro-mechanical interfaces

- Computer-assisted quality control

- Repetition of a programmed task

Find the robotic application you are looking for

Good welds

In a dedicated secure area, robots will weld thousands of parts without tiring.

Strength and precision for your handling needs

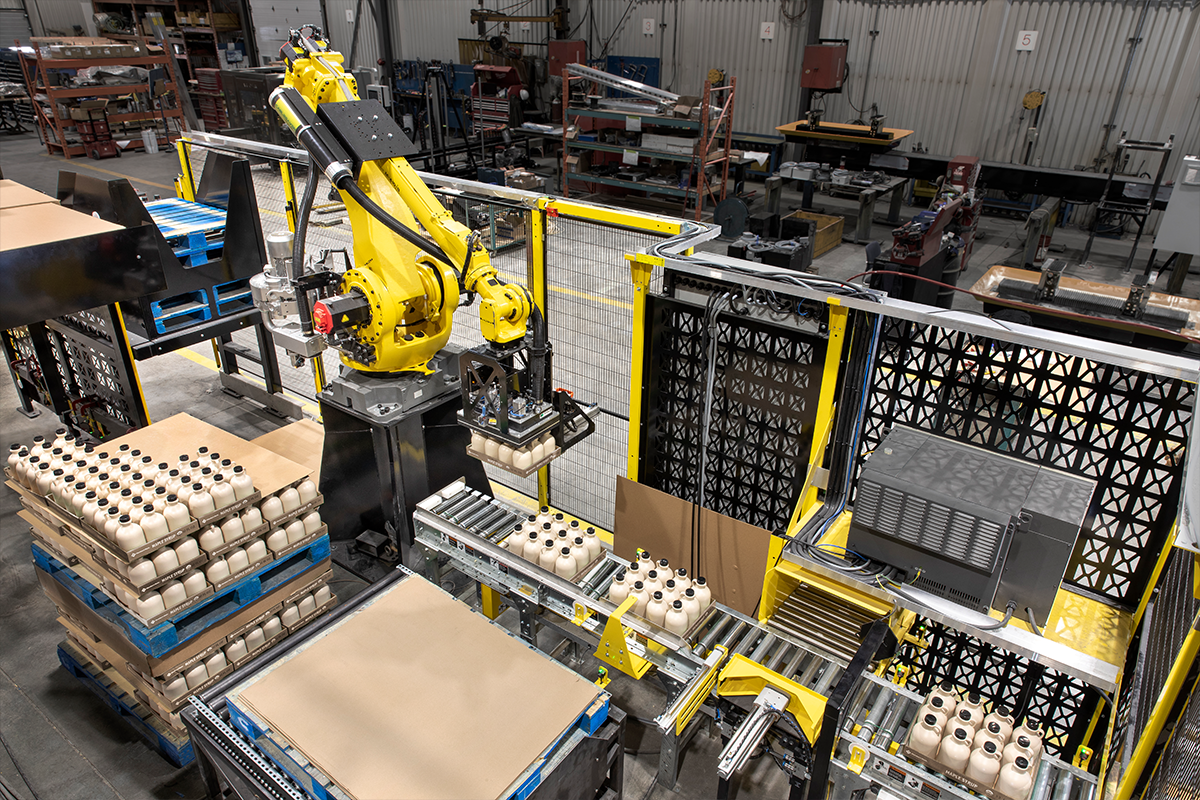

Have robots move goods repeatedly instead of your labour force and eliminate risks of work-related injuries.

Palletizing possibilities

Our robots analyze stacking options to optimize the storage of your bags, boxes, and crates.

Collaboration between robots and workers

Collaborative robots work in the same production space as your skilled workers to perform several tasks at the same time.

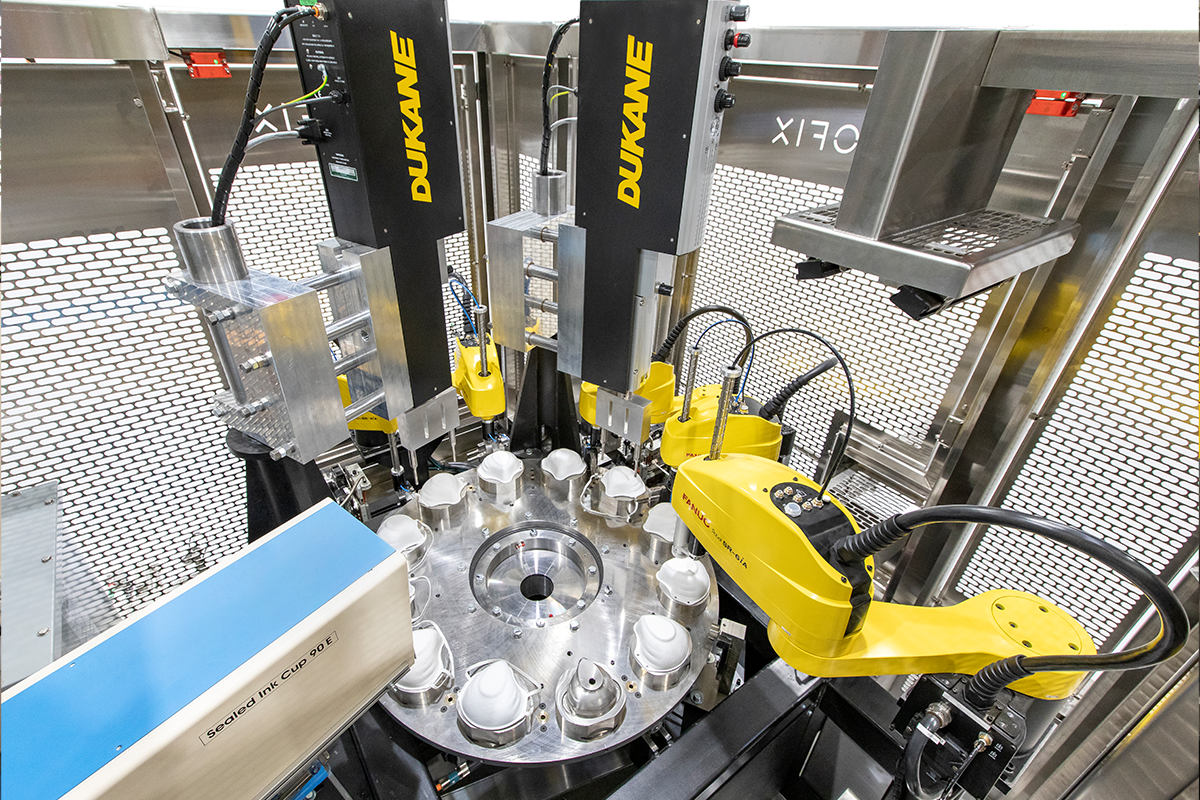

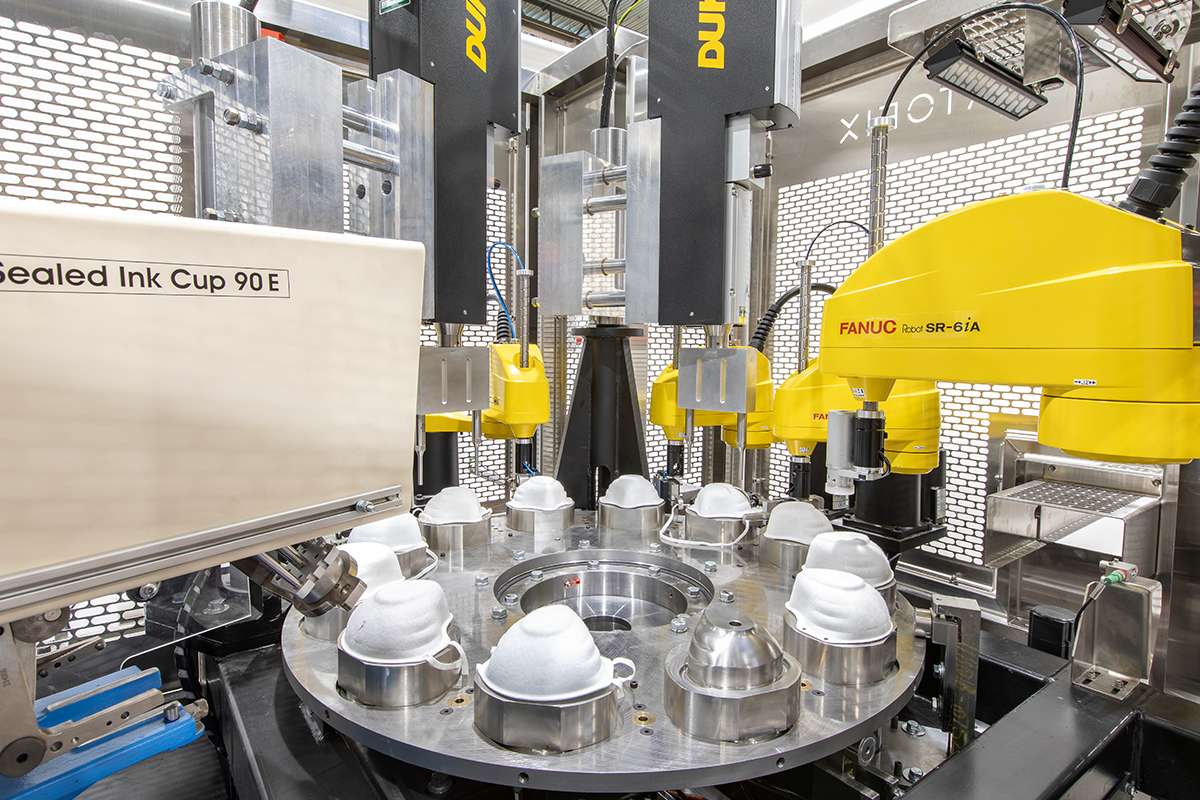

Assembly

Our robots repeatedly assemble parts while maintaining consistent quality to optimize the workflow.

Retrieving parts

Using 2D/3D vision, our robots target the location of parts in a bin before retrieving them.

Quick and careful positioning

Robots place components in a specific order to keep the production line running.

Keep up the pace

Robots can supply other equipment with the necessary inputs or off-load manufactured products at the required speed.

Packing your products

Robots are programmed to insert and stack your products inside boxes.

Tightening screws

Equipped with the appropriate tool, robots will screw the fasteners on your panels, products, etc.

Repetitive cutting and shaping

Robots will shape your parts from start to finish.

The ultrasonic arm

In compliance with your food safety standards, our robots, equipped with an ultrasonic blade, will perform the most complex and diversified tasks to cut your food products.

What kind of benefits can a robot provide you with?

- Use of labour on valued-added tasks

- Easy integration into your operation processes

- Increased speed of start-up times during product and batch transitions

- Increased production capacity

- Control of operating costs

- Human error risk reduction

- Standardization of existing procedures

- Reduction of direct or indirect labour costs

- Adaptation to challenging working conditions in the plant